- TOSIZE.be

- Do it yourself

- DIY Projects

Budget-friendly wind springs made of okoume plywood primed, by Eric

Create this project yourself with sheet material cut to size by TOSIZE.be!

Eric

Average

2 minutes

Description

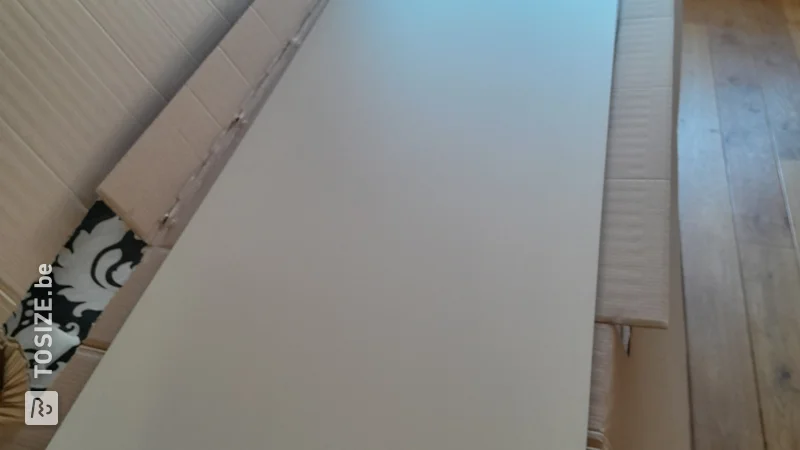

The old weatherboards were too bad to repaint and the connection between the parts was screwed. I made new wind springs with a glued connection of the miter sawn parts

Replacing wind springs myself

I took the dimensions of the old wind springs and ordered the required lengths from TOSIZE.be. Because I no longer wanted to screw the parts, I had one side of all 4 panels sawn with a miter.

Then I used the old parts as a template to mark and cut them to the exact size and shape. sawn to the correct shape.

The long parts, with the mitered side, were attached to each other with duct tape so that a hinged effect was possible. Then filled the resulting V-shaped groove with waterproof wood glue and, after drying for a while, put it into the correct shape and fixed it with 4 pieces of tape.

After drying, the tape was removed, the sharp corner of the blunt sanded and all sawn edges with edge primer treated.

After fitting and a very small piece of adjustment work installed. And has just been dismantled again so that the painter can give all invisible sides a lick of paint

Final size: What are the outside dimensions?

230.0 x 27.0 x 9.0 cm

190.0 x 27.0 x 9.0 cm

Tip! Also check out our handy DIY tips!

What now?

This is a project for inspiration. Because our assortment has changed, (some of) the products are no longer available.

View all sheet materials