- TOSIZE.be

- Wood and sheet material

Phenolic plywood

Phenolic plywood sheets are real powerhouses! Nowadays, there are many types of phenolic plywood sheets. It consists of plywood with a plastic (phenolic resin coating), which serves as a top layer. This top layer is applied at the top and bottom. Depending on the type of phenolic plywood sheet, it is finished with this smooth coating on 1 or 2 sides. This makes the sheet suitable for many applications. Phenolic plywood is suitable for intensive use indoors and outdoors, provided the edges are properly treated.

Due to the hard phenolic resin coating, also known as epoxy coating, this sheet material is immediately ready for use and does not need to be finished.

Order cut-to-size phenolic plywood or concrete plywood sheets

This is where you buy phenolic plywood sheets, also known as concrete plywood, sawn with millimeter accuracy. You can easily specify the desired shapes and dimensions and any finishes online. Do you have a big project with phenolic plywood? This is not a problem either. We are your partner for phenolic plywood and all your cut-to-size wood projects.

Phenolic plywood sheets: what are they?

Phenolic plywood is a very strong sheet material that has been specially developed for the formwork during concrete pouring. It falls within the category or wooden sheets. The phenolic plywood sheets are provided with an epoxy top layer, which consists of 2-component synthetic resin. This makes said layer impact resistant, scratch resistant and waterproof.

Pouring concrete requires very strong formwork, of course. In addition, the concrete must not adhere to the material while drying in the formwork. Phenolic plywood sheets were developed with these conditions in mind. Once the concrete has hardened well, the phenolic plywood can be removed effortlessly. Today, phenolic plywood sheets are used for many different purposes.

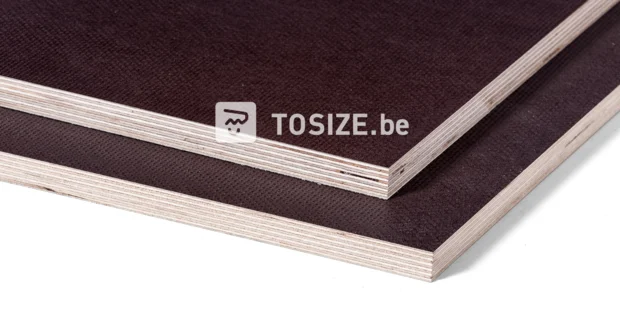

The structure of phenolic plywood sheets

Phenolic plywood sheets consist, just like plywood, of glued veneer layers. The thin wooden layers are glued crosswise to each other to create a strong and stable sheet that does not or hardly bend. The durability of phenolic plywood sheets varies depending on the type of wood. Hard phenolic plywood types, such as birch and hardwood, are very durable.

Properties of phenolic plywood

Phenolic plywood is extremely suitable for use outdoors or in humid conditions. Due to the hard plastic phenolic resin coating, no water can penetrate. The veneer layers from which phenolic plywood is constructed are bonded externally.

Phenolic plywood does not bend, even under heavier and prolonged loads, because the material is very strong.

Types of phenolic plywood sheets

In our web shop, you can order various types of phenolic plywood sheets online. The best-known phenolic plywood variants are made up of birch veneer layers or hardwood veneer layers. The name, phenolic plywood, says it all. The core consists of cross-glued veneers of a certain type of wood. This may be birch in one case, or tropical hardwood in another.

Our range of phenolic plywood sheets includes the following types:

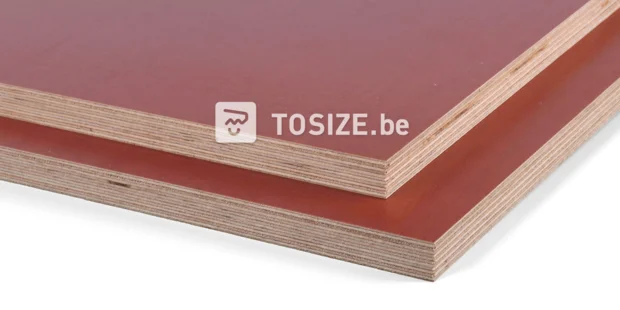

Different colours and top layers of phenolic plywood

There are a number of variants of phenolic plywood sheets available in our web shop. The difference between these sheet materials is the colour or structure of the phenolic resin coating. Furthermore, all phenolic plywood sheet materials have a number of properties in common:

- All sheets are externally bonded

- Standard phenolic plywood has a 120 g/m2 phenolic resin coating

- All plates can take a beating, but are sensitive to scratching

- All top layers are water repellent

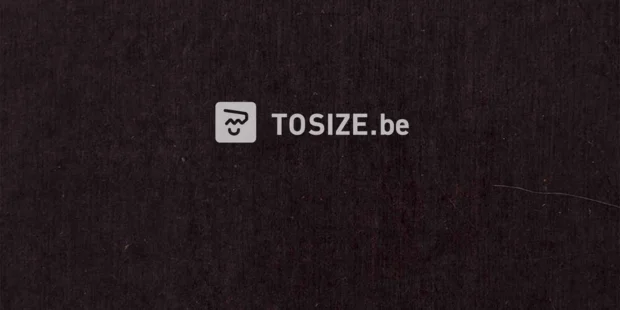

Phenolic plywood with a phenolic resin top layer

The phenolic plywood sheets are provided with a strong epoxy top layer, which consists of 2-component synthetic resin. This makes said layer impact resistant, scratch resistant and waterproof. Due to the strong, waterproof phenolic resin coating, these sheets can be used well in humid conditions, as this layer is water repellent. However, the smooth phenolic resin coating is sensitive to scratches, which makes this sheet material less suitable for decorative purposes.

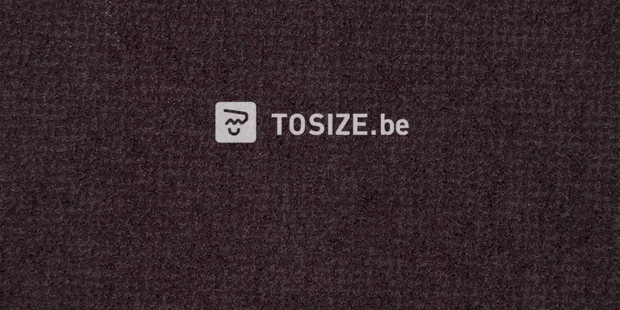

The epoxy layer ensures a tight and smooth finish of the sheet, except with phenolic plywood antislip. This phenolic plywood variant has a wire mesh structure on one side. This makes this variant suitable for use as a floor element in animal pens, trailers, tent floors or commercial vehicles. By default, these top layers are not UV resistant, which causes the phenolic plywood to discolour over time.

Phenolic plywood sheets and moisture

Phenolic plywood was developed because strong sheets were needed for concrete form work. Pouring concrete requires strong form work. In addition, the concrete must not adhere to the material while drying in the form work. The top layer of phenolic plywood has been specially developed for this purpose and is water repellent. However, the edges must be properly finished to prevent the ingress of moisture. This can easily be done with an edge sealer.

Available thicknesses of phenolic plywood

Phenolic plywood is strong and available in various thicknesses, so that there is always a perfect thickness for your specific application. The most common thickness is 18 mm. In our web shop, you can order Phenolic Plywood 9 mm, Phenolic Plywood 12 mm, Phenolic Plywood 15 mm and Phenolic Plywood 18 mm and have them cut to size.

Common applications of phenolic plywood

Phenolic plywood is also known as concrete forming plywood due to the fact that this sheet material is extremely suitable for making concrete formwork. Nowadays, it is used for multiple purposes, such as floor parts, bodywork finishing, stable construction, facade cladding or advertising applications. However, it is important to treat the sheet edges well when used outdoors. While the phenolic resin coating is water repellent, the sheet edges are not.

Phenolic plywood sheets are very high-quality, strong and durable wooden sheets that you truly have a plethora of options with. If you are looking for a wood type that will not quickly lose its quality under various circumstances, a phenolic plywood sheet is often a good choice. Phenolic plywood sheets were previously mainly used on construction sites and in industry. Nowadays, we see that private individuals increasingly opt for phenolic plywood sheets to make beautiful furniture for their own home, for instance.

DIY tips for assembling and finishing phenolic plywood

Curious to know what DIY projects others have used phenolic plywood sheets for? Take a look at all the projects of handymen that preceded you on our DIY and inspiration blog. A blog full of other people's job projects, DIY tips and project examples. How handy is that?

Alternatives to phenolic plywood

Is phenolic plywood not what you're looking for? Take a look at our entire range of wooden sheets; everything can be cut or milled down to the millimetre and you can find the ideal wood type for your next project.

Phenolic plywood vs. plywood with an HPL top layer

Phenolic plywood is a sheet material developed for construction purposes. Would you like to use these sheets as a table, wall panel or other visible application? Then realise that the phenolic plywood is sensitive to scratching. Looking for finished wooden sheets for visible applications? Then opt for plywood with an HPL top layer, Trespa® or furniture board.